Sugar production

To supply our production facilities with sugarbeet, we rely on long-term partnerships with local farmers that benefit everyone. That's why we are committed to paying fair prices for beet today, constantly innovating to safeguard beet cultivation, and supporting farmers so that we can increase beet supplies and utilize our factories to full capacity.

Regional production facilities and short distances to our suppliers and customers are a key element of our value creation strategy. Our strength as AGRANA Zucker lies in our experience: we know exactly how to produce, store and deliver sugar efficiently. There is something else we know from experience: we can do more. We will use the ability to constantly improve to produce even more efficiently and thus reduce our environmental footprint.

#ResponsibilityInGrowth

Sugar production

Sugar, or sucrose to be precise, is made from sugar beet grown in Europe. This involves purified juice being extracted from washed and cut sugar beet in a series of process steps. This juice is then concentrated until the sugar contained crystallises.

No additives are added in the process. The sugar is purified by repeated recrystallization and pure, clear crystals are obtained, which appear white due to light scattering. The sucrose content of these crystals is almost 100%. Sugar is therefore a highly pure foodstuff that can be stored almost indefinitely if properly stored. It is a carbohydrate in its purest form and is therefore of particular importance to our lives. Learn more about sugar extraction.

The smallest sugar factory

THE SUGAR BEET PLANT (beta vulgaris saccharifera)

is a biennial plant belonging to the goosefoot family. The taproot, the so-called beet, which is used to produce sugar, forms during the growing phase in the first year. A flower and seeds form during the growing phase of the second year. This relies on the sugar stored in the beet. With a sugar concentration of 16 to 20%, the sugar beet offers the highest yield among sugar-producing plants (sugar beet and sugar cane). The water content is around 75%.

LEAVES OF THE SUGAR BEET

With the aid of solar energy and the chlorophyll in its leaves, the sugar beet plant converts carbon dioxide from the air, water and minerals in the soil into sugar. This process is called photosynthesis. The sugar beet foliage are left on the fields during harvesting.

HEAD OF THE SUGAR BEET

The head of the sugar beet plant, from where the leaves branch off, contains many non-sugar materials and therefore needs to be removed during harvesting.

ROOT OF THE SUGAR BEET

The sugar produced during photosynthesis is stored in the root of the sugar beet. The lighter areas are those in which the concentration of sugar is particularly high.

Produced products

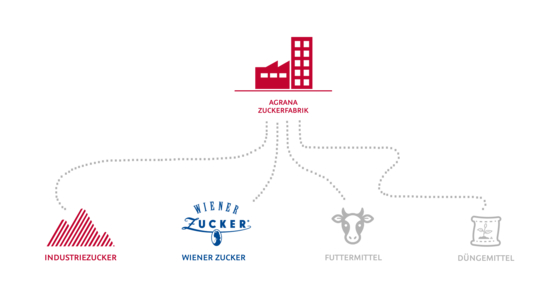

Sugar is versatile! Our sugar products - whether from conventional cultivation or in organic quality - are used in the food industry and other sectors or sold to end consumers via food retailers. In addition, we also produce feed for animal husbandry and fertilizer for agriculture.

2. Raw Juice Production

The sugar is extracted from the cossettes by means of hot water (around 70 °C) in a diffuser, with the cossettes moving in the opposite direction to the water flow (counter-flow-principle), in a process known as extraction. The raw juice or liquor obtained contains around 98% of the sugar in the sugar beet as well as organic and inorganic constituents (so-called non-sugars) from the beet.

3. Juice Purification

The non-sugars in the raw juice are bound and extracted by means of the natural substances lime (CaO) and carbonic acid gas (CO2) which are produced in the site‘s own lime kiln.

4. Filtration

The flocculatable insoluble non-sugars and the lime are filtered off in filter units. The filtrate is known as thin juice and the filter residue as carbonation-lime. This is an important soil improver and fertilizer which is spread on the fields.

5. Thick Juice Production

The thin juice is evaporated in hour-long steaming process to produce thick juice. The operation of on-site power plants provides the considerable quantities of energy needed for sugar production. The steam produced in the high-pressure boilers is used in the turbogenerators to produce electricity. The waste steam from the turbines is used as process heat (cogeneration) in order to heat the evaporator station.

7. Centrifugal

The sugar crystals are separated from the syrup by means of centrifuging. The separated syrup is subjected to a further two crystallisation process.

8. Sugar

The pure, crystal-clear sugar appears white when subjected to white light. White sugar contains at least 99.7% sucrose. The remainder is in effect moisture.

10. Molasses

The syrup separated off during the final crystallisation step is known as molasses. The molasses contains the non-crystallised sugar (6-9% of the sugar content of the beet) as well as the soluble non-sugars from the sugar beet. Molasses is a valuable ingredient for the baking yeast and animal feed industry as well as for the production of alcohol.