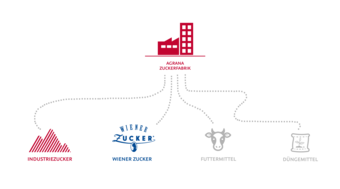

Getting the most out of sugar. Various by-products are also processed rather than simply being disposed of. At AGRANA, we practice a sustainable business cycle. We manage to use nearly 100 % of the agricultural commodities involved in sugar production.

An example of this is molasses, the syrup extracted during the last crystallisation process. Molasses contains non- crystallised sugar (6 to 9 % of the sugar contained in sugar beet) as well as the soluble non-sugars found in the sugar beet. Molasses is a valuable product which is processed to make baking yeast and animal feed as well as being used to make alcohol. The sugar beet cosettes left over in the extraction tower are also processed further. After being mechanically pressed and molasses added, the cosettes are dried, pressed to form pellets and sold as animal feed.

Zero Waste Principle

Through efficient use of raw materials, technical innovation and product development, we have achieved almost complete (98.6 - 99.9%) raw material utilisation in all segments. The Group-wide principle of zero waste is beneficial in two dimensions: First, AGRANA's business success depends on the efficient use of the agricultural inputs, such as sugar beet, grain, potatoes and fruit. And second, wasting nothing is also consonant with the high standard of corporate responsibility that AGRANA strives to honour in all its plants worldwide.

1 tonne of sugar = around 1 tonne of by-products (feed & fertiliser). By-products make an important economic contribution and fulfil an ecological function. Minerals and nutrients are returned to nature as part of a closed cycle.

You can find out more about the value chain in the Sugar segment here: